Our Process

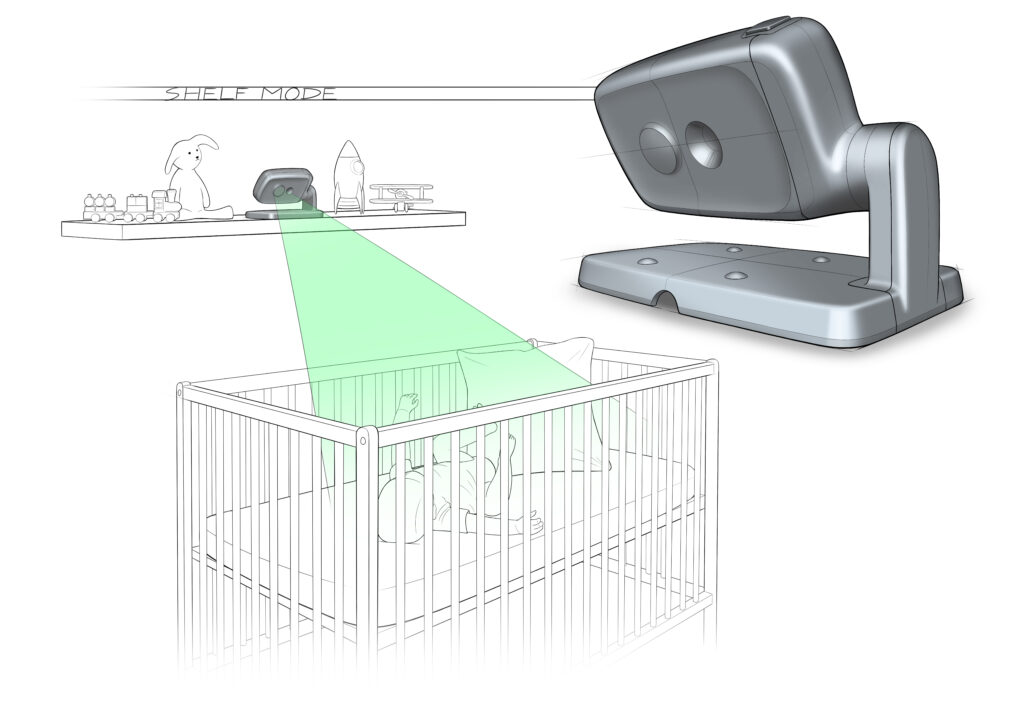

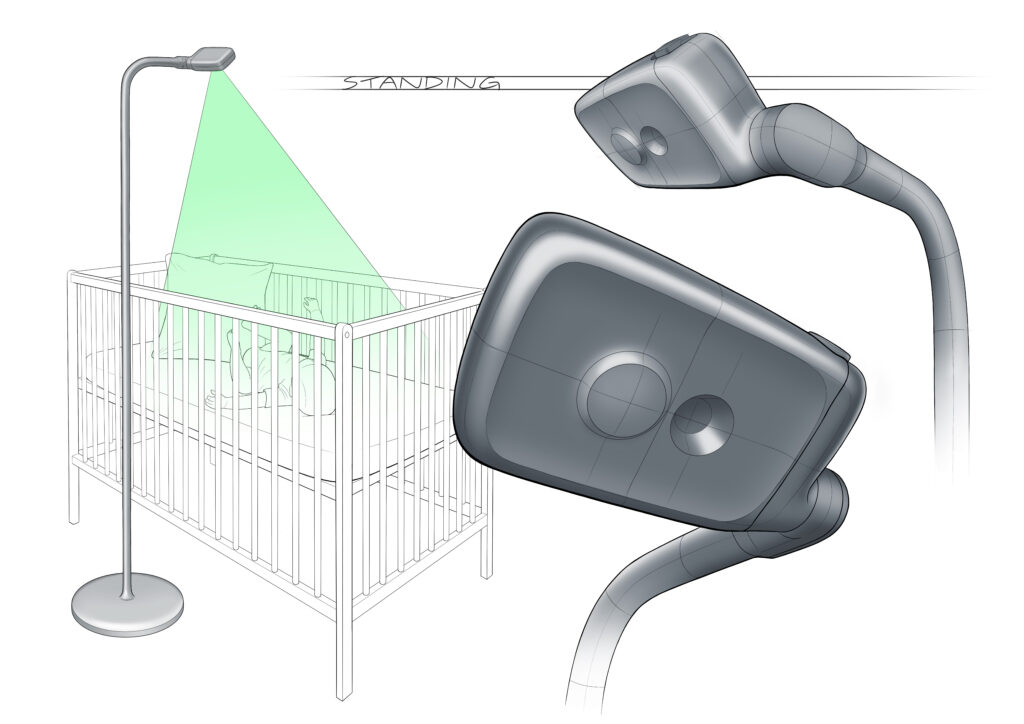

From the outset, our goal was to create a product that was not only intuitive for parents but also robust, reliable, and ready for scalable production. The industrial design phase began with exploring form factors that balanced approachability with discretion, something parents would feel comfortable placing in any room of their home. Early CAD explorations and physical mock-ups allowed us to refine ergonomics, while maintaining a compact footprint.

We prioritized Design for Manufacturing (DFM) at every stage, making deliberate choices in materials, finishes, and component assembly to ensure efficiency, consistency, and quality at scale. This included specifying surface textures and tolerances that supported both durability and a premium feel.

Through iterative prototyping, we validated not only usability but also manufacturability, testing injection-molded samples, refining tooling strategies, and ensuring the design translated seamlessly from prototype to production line. The result is a product that delivers advanced AI-powered monitoring within a carefully engineered form, optimized for both the parent experience and streamlined, cost-effective manufacturing.